Description

Now anyone with a standard reloading press can benefit from advanced benchrest techniques.

The amount of resizing provided by conventional reloading dies has always been dictated by the manufacturing tolerances (SAAMI specifications) of the brass cartridge case itself. Reloading die manufacturers have been forced to design the neck diameter of their dies small enough to accommodate the thinnest possible brass.

This may be as much as .008″ – .010″ smaller than the maximum cartridge dimensions typically shown in most reloading manuals.

Since the majority of cases that the reloader is likely to encounter in the field are thicker than the minimum specifications that the dies were designed for, case necks are often resized excessively.

It can be easily demonstrated that excessive resizing of the cartridge case quickly leads to stress distortion and concentricity problems. The new Type S – Bushing Style Dies offer a simple solution to this age old problem.

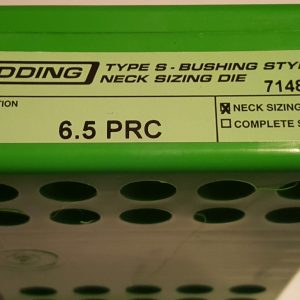

The new Type S – Bushing Style Neck Sizing Die provides reloaders with a simple means to precisely control case neck size and tension.

- Uses interchangeable sizing bushings available in .001″ increments.

- The adjustable decapping rod allows positioning the bushing to resize only a portion of the neck length if desired.

- Concentricity is enhanced by the ability of the resizing bushing to selfcenter

- on the case neck.

- The decapping rod is supplied with a standard size button. This is especially useful for reloaders who are using commercial brass as is.

- A decapping pin retainer is also supplied with most Type S – Bushing Dies except 17 and 20 Cal. This enables neck sizing without the use of the size button for those who sort and/or turn case necks for uniformity.

All dies are supplied without bushings.

LIMITED TO STOCK ON HAND